The experimental SAMOROST project has turned science fiction into reality

The SAMOROST project is revolutionizing sustainable living with the completion of a unique house that uses mycocomposite as a key building material. Developed after two years of research, this innovative mycelium-based material offers a wide range of applications – from thermal and sound insulation to designer tiles and furniture. In the spring, the house will embark on a tour of Czech cities, including Prostějov, České Budějovice, Jihlava and Pardubice, to inspire a sustainable lifestyle.

CS Building Savings Bank Burinka (member of Erste Group) and the MYMO Association, which is behind the project, have also completed research in the field of green buildings and circular construction, in cooperation with the Czech Technical University. A life cycle assessment (LCA) evaluating the potential environmental impacts across the life cycle of mycocomposite has confirmed its significant environmental benefits over traditional materials such as polystyrene. The study was prepared by the University Centre for Energy Efficient Buildings of the Czech Technical University (UCEEB), whose mission is to help reduce energy consumption and the environmental burden in the construction industry.

Mycocomposite: the Future of Sustainable Construction

The SAMOROST project started in 2023 through cooperation between CS Building Savings Bank Burinka (member of Erste Group) and the MYMO Association, i.e. experts from the Czech Technical University and the Mykilio startup. Their aim was to verify whether mycelium could be used as a sustainable alternative to commonly used building materials. After intensive research and testing, they are now presenting the SAMOROST house – an innovative building that uses mycocomposite in several key functions. The material serves as thermal and sound insulation, in the interior as decorative panelling or a basis for furniture production.

The SAMOROST house is a wooden building that has been thermally insulated with mycocomposite panels. The new material was used while maintaining the standard technological procedures of construction for correct building insulation, including the application of a vapour barrier preventing moisture from getting into the structure’s interior and additional waterproofing placed under the wooden roofing. The entire structure therefore combines natural materials with modern processes.

“One of the tense elements during construction was working with circular skylights and installing them. None of our implementation team had experience with this technical solution. It was necessary to correctly estimate the reserves for inserting them into the structure – so that they were not too small, so installation would be possible at all, but at the same time ensure there would be no unnecessary heat leakage. We also had to ensure that the upper overhangs of the beams could support the steel load of the ceiling windows. When doing experiments, you often solve some things in the process, and that’s what I like about it. What’s crucial is that there’s always a solution,” said Kateřina Sýsová from the Czech Technical University and the MYMO Association.

The experimental house, whose appearance resembles two parasol mushrooms growing in a forest, measures 3.04 x 7.14 meters. 1,800 kg of mycocomposite was used for its production. The base material was grown for a total of 21 days and subsequently processed for 3 months. The preparation of mycelium-based material therefore took a total of 4 months.

Progress building the SAMOROST house (from top left: installing mycocomposite panels, fixing hydrophobic film, attaching shingles, exterior view, installing skylight, attaching window) Source: CS Building Savings Bank Burinka (member of Erste Group)

LCA Study: Mycocomposite is Environmentally Friendly

“At CS Building Savings Bank Burinka (member of Erste Group) we have long been looking for ways to promote more sustainable housing with a smaller environmental footprint. Our previous projects, such as the Prvok 3D Printed House, showed that innovation in construction can change the way society thinks about sustainable housing. And mycocomposite is a material that has enormous potential in this regard. The SAMOROST house is confirmation that it can be done. It is a challenge for all manufacturers and builders. They are the ones who can move mycocomposite into industrial production,” said Libor Vošický, Chairman of the Board of Directors of CS Building Savings Bank Burinka (member of Erste Group).

SAMOROST is not only an experiment, but a real step towards greener construction. As a building material, mycelium’s advantages are minimal carbon footprint, biodegradability and low-energy production. The UCEEB study confirms its advantages over traditional materials, especially in terms of sustainability and recyclability.

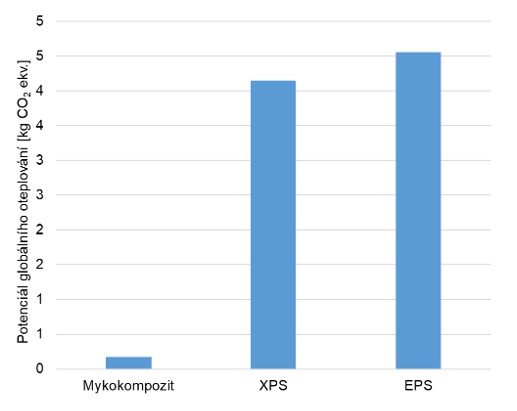

“We found that mycocomposite production causes almost 20 times lower potential impact on climate change than extruded or expanded polystyrene production. The global warming potential (GWP, expressed in kg of CO2 equivalent per kg of insulation panel) for mycocomposite is 0.17, while for extruded polystyrene this value is 4.15 and for expanded polystyrene 4.56,” explained Jan Pešta from UCEEB, continuing: “Moreover, with regard to fossil raw material consumption – in the ADP-fossil fuel indicator, mycocomposite has a much lower potential impact than polystyrene. The abiotic depletion potential for fossil resources (ADP-fossil) is 5.18 MJ/kg for mycocomposite, compared with 88.9 for extruded polystyrene and 95.9 for expanded polystyrene.”

The graph shows a comparison of the global warming effects of mycocomposite material, extruded polystyrene (XPS) and expanded polystyrene (EPS). Source: UCEEB and CS Building Savings Bank Burinka (member of Erste Group)

SAMOROST House Will Tour the Czech Republic

The SAMOROST house will set off on a tour of the Czech Republic in the spring, when those interested will be able to see it for themselves. The house is unique in the world. It is a direct application of science and research. The demonstration of the use of mycocomposite in the house will bring the public closer to the possibilities of natural materials in sustainable construction. Through the use of mycocomposite, the project developers want to broaden the view of green buildings, which represent significant savings in energy and raw materials.

People from Prostějov, České Budějovice, Jihlava and Pardubice can look forward to seeing the house. Experts from the SAMOROST project will also visit many other places, where they will present the material to people as part of a workshop or interactive lecture. The roadshow’s full itinerary will be available at www.inovaceodburinky.cz.

About SAMOROST

The SAMOROST project was launched in April 2023 with the aim of finding a suitable way to implement the subfloor-based material in the construction industry, thus supporting its sustainable development. The project is backed by CS Building Savings Bank Burinka (member of Erste Group) and the MYMO association.

2023 was the year of matter and design. Experts involved in the project investigated mycocomposite and carried out a series of tests to verify its properties. The results of the tests yielded crucial information: mycocomposite can replace non-organic materials (e.g. polystyrene) that are commonly used in the construction industry. The highlight of 2023 was the exhibition of furniture and interior accessories made from mycocomposite at the international Designblok festival. The aim was to show that mycocomposite also has a place in design.

In 2024, project representatives announced that they have started production of the SAMOROST house, which will demonstrate the possibilities of mycelium involvement in sustainable construction. The house will be completed by the end of the year and will be presented to the public in 2025.

The creation of the SAMOROST House was supported by the Minister of the Environment Petr Hladík by granting patronage.

What is the MYMO Association?

The MYMO association brings together personalities from the field of research who have set themselves the goal of laying the foundations of mycelial architecture in the Czech Republic. These are experts from the Institute of Model Design of the Faculty of Architecture of the Czech Technical University (Molab) and experts from the company Mykilio. It is for this purpose that Kateřina Sýsová, Karolína Petřeková, Petra Jašicová, Jiří Vele, Matěj Róth, Jakub Seifert and Tomasz Kloza are researching and developing a material based on mycelium mushrooms. At the same time, together with Burinka, they want to raise awareness of the potential of mycelium in construction among the professional and lay public.

About the CS Building Savings Bank Burinka (member of Erste Group)

For thirty years, we have been providing clients with advantageous building savings accounts, loans, mortgages and comprehensive financial advice. Currently, we focus on financing energy-sustainable renovations and related grant consultancy. Our profile as a renovation bank is reflected not only in the products and services we offer, but also in our communications. We have prepared a 10-part series called Economical Renovations with Burinka. The combination of expert articles and light-hearted videos will convince anyone who is hesitant to start an economical renovation project. We share low-cost tips on how to save money in individual rooms of your home here.

As a building savings bank, we also feel a commitment towards the construction industry, which we fulfil by supporting innovative processes and materials used in house construction. You can find more about projects brought to fruition to support science and research in the construction industry on www.inovaceodburinky.cz/en.

Contact for media

Monika Kopřivová

External Communications Manager of building savings bank Burinka (meber of Erste group)

E-mail: monika.koprivova@burinka.cz

Mobile: +420 724 097 666